Packaging printing is often treated as a single topic, yet in commercial practice it involves multiple technical layers that must work together to deliver the desired final result. In many projects, terms like printing processes, color systems, and surface finishing are used interchangeably, which can lead to misunderstandings in feasibility, quality control, and cost estimation.

This guide clarifies these distinctions and provides a material‑based overview of how different printing decisions function across metal, plastic, and paperboard packaging.

Packaging printing processes determine how ink is transferred onto the substrate, and they vary significantly depending on the material, production volume, and durability requirements. Below is a summary of common printing processes and their material applicability.

| Printing Process | Applicable Packaging Materials | Common Packaging Forms | Process Characteristics |

|---|---|---|---|

| Offset Printing | White‑coated paperboard, greyboard, coated paper | Folding cartons, retail boxes | High resolution and color fidelity; suitable for detailed imagery; optimal on smooth paper surfaces |

| Gravure Printing | PET, OPP, CPP films, aluminum foil, flexible laminates | Flexible packaging, labels, sleeves | Excellent ink density and saturation; cost‑effective at high volumes; subtle detail less than offset in some cases |

| Flexographic Printing | Corrugated board, kraft paper, plastic films | Corrugated boxes, plastic bags, labels | Fast, versatile, compatible with many inks; ideal for continuous registration on varied substrates |

| Screen Printing | Steel tinplate, aluminum, hard plastics, glass | Metal cans, decorative boxes, rigid containers | Thick ink layers and strong adhesion; effective for metallic and textured surfaces |

| Digital Printing | Paperboard, coated stocks, some plastics | Short runs, customized packaging | No plates required; flexible and quick; higher per‑unit ink cost |

| Pad Printing | Metal, plastic, curved surfaces | Caps, lids, small parts | Transfers into hard‑to‑reach or irregular zones |

| Heat Transfer Printing | Plastic, metal | Labels, decorative finishes | Transfers pattern via heat; limited abrasion resistance |

| Inkjet Printing | Paperboard, plastics, metal coatings | Dates, codes, variable data | Excellent for variable information; not decorative per se |

Professional Notes (Printing Processes):

Printing processes define technical feasibility and cost impact but do not automatically dictate final color quality.

Screen printing remains a strong choice for metal surfaces due to ink thickness and adherence.

Gravure excels in consistent, high‑speed runs but requires economies of scale.

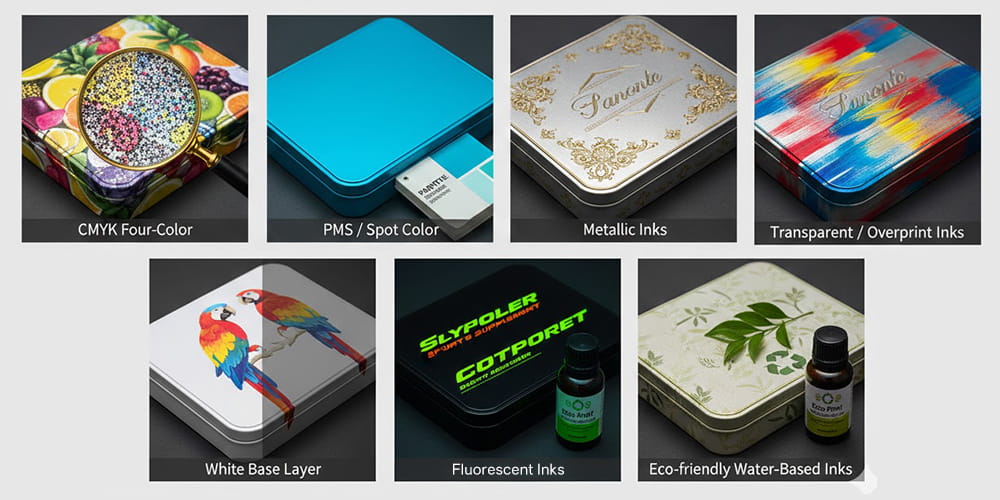

Color systems determine how colors are defined, mixed, and reproduced. Choice of color system depends on substrate characteristics, brand color requirements, and visual goals.

| Color System | Applicable Materials | Key Characteristics |

|---|---|---|

| CMYK Four‑Color | Paperboard, plastic films, coated surfaces | Standard for reproducing full‑color images; quality depends on press profile |

| PMS / Spot Color | Paperboard, metal, plastics | Precise, consistent brand colors; best for logo and solid colors |

| Metallic Inks | Metal, special decorative stocks | Adds shine and luster; suited for premium packaging |

| Transparent / Overprint Inks | Metal, plastics | Enhances depth by letting substrate show through |

| White Base Layer | Metal, dark plastics | Ensures top colors appear vivid on non‑white substrates |

| Fluorescent Inks | Paperboard, plastics | High visibility; often used for attention‑grabbing graphics |

| Eco‑friendly Water‑Based Inks | Paperboard, corrugated board | Improved environmental profile; sometimes lower saturation |

Professional Notes (Color Systems):

Color systems should be chosen based on both visual goals and substrate behavior.

For metallic substrates, transparent and white‑base strategies may deliver more expected results than simple CMYK mixing.

Brand color consistency often requires spot color systems irrespective of substrate.

Surface finishing determines how printed packages look and feel after printing. These effects influence perceived quality and functional performance.

| Surface Effect | Pictures | Applicable Materials | Effect Characteristics |

|---|---|---|---|

| Gloss Varnish |  |

Paperboard, metal, plastics | High shine and visual impact; enhances color intensity |

| Matte / Frosted Finish |  |

Paperboard, metal, plastics | Soft, low‑reflection finish; perceived as premium |

| Spot UV / Selective Varnish |  |

Paperboard, metal | Enhances specific areas for contrast |

| Embossing / Debossing |  |

Paperboard, tinplate | Creates tactile depth; strengthens brand cues |

| Brushed Finish |  |

Aluminum, steel | Distinct metal grain effect; industrial aesthetics |

| Wrinkle / Specialty Coatings |  |

Metal | Adds functional texture or anti‑slip feel |

| Film Lamination (Gloss/Matte) |  |

Paperboard | Protective layer that enhances durability |

| Food‑Grade Internal Coatings |  |

Metal packaging | Prevents corrosion and contamination in food use |

Professional Notes (Surface Effects):

Surface effects should be coordinated with material capabilities; e.g., embossing on metal demands distinct tooling versus paperboard.

Matte and frosted finishes can reduce perceived color contrast and must be balanced with underlying color systems.

Rather than viewing printing processes, color systems, and surface effects as isolated choices, they function as layers in a coordinated system. Each layer influences not only aesthetics but also production viability and cost.

Paperboard packaging typically emphasizes color fidelity and cost efficiency, aligning well with offset and digital printing paired with robust color management.

Plastic & Flexible films prioritize speed, durability, and adhesion—making flexo and gravure popular choices.

Metal packaging, including tin boxes and aluminum cans, demands ink adhesion and surface handling that often favors screen printing and specialized coatings.

By understanding these layers, designers and manufacturers can reduce common production issues and deliver consistent, high‑quality results.

Related reading

Related reading

Success in plate-making and printing for tinplate packaging is ultimately judged by whether the printed piece faithfully reproduces the original artwork—retaining its colour, texture, and artistic intent......>> Read More

Tinplate printing belongs to the domain of specialty or metal printing, distinct from conventional paper printing in both process and equipment......>> Read More

For further authoritative context and technical background, consider the following:

Journal of Packaging Technology and Research. (n.d.). Springer. Retrieved from https://link.springer.com/journal/41783

Packaging Technology and Science. (n.d.). Wiley Online Library. Retrieved from https://onlinelibrary.wiley.com/journal/10991522

International Journal of Printing and Packaging Technology (IJPPT). (n.d.). IAEME. Retrieved from https://iaeme.com/Home/journal/IJPPT

Song, H., Xu, M., & Zhang, L. (Eds.). (2025). Advances in Printing, Packaging and Communication Technologies. Springer. https://link.springer.com/book/10.1007/978-981-96-4467-4

Cao, T. (2024). Inkjet printing quality improvement research progress: A review. Heliyon, 10(10), e30163. https://doi.org/10.1016/j.heliyon.2024.e30163

Witek‑Krowiak, A., Szopa, D., & Anwajler, B. (2024). Advanced Packaging Techniques—A Mini‑Review of 3D Printing Potential. Materials, 17(12), 2997. https://doi.org/10.3390/ma17122997