Tinplate, also known as low-carbon steel coated with tin, plays a pivotal role in packaging industries worldwide. Comprising a base steel sheet, tin-iron alloy layer, pure tin layer, chromium oxide film, and a protective oil coating, tinplate has become essential in food, beverage, chemical coatings, and gift packaging, accounting for approximately 90% of total demand. Other applications, such as aerosol cans, bottle caps, and electronic components, make up the remaining 10%.

The tinplate market in China is primarily dominated by Baosteel and Wuhan Steel (WISCO), with prices averaging around $1,000 per ton. Printing and prototyping require significant investment, often costing around $2,000 per proof, making large-scale production more cost-effective than small-batch runs.

| Supplier | Price per Ton (USD) | Typical Application | Printing Difficulty |

|---|---|---|---|

| Baosteel | 1,000 | Food, Beverage, Gifts | High |

| Wuhan Steel | 1,000 | Industrial & Packaging | High |

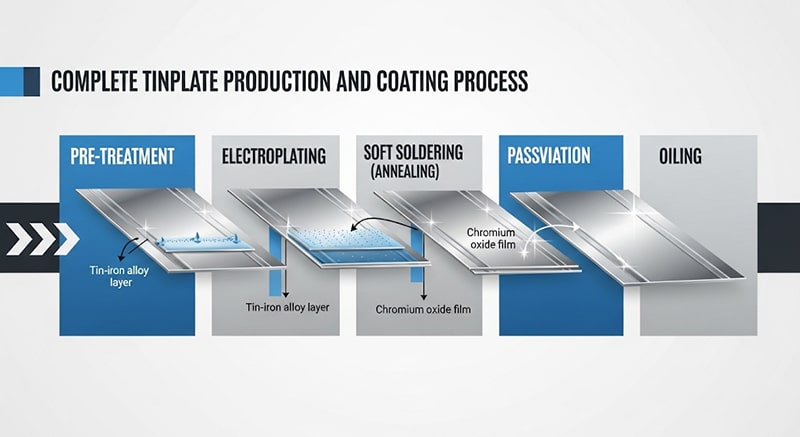

Unlike ordinary low-carbon steel, tinplate is corrosion-resistant due to its tin coating. The process involves:

Surface Pre-Treatment: Removes oxides and oils to prepare a clean surface.

Electroplating: Tin anodes dissolve into ions and deposit onto steel cathodes.

Soft Soldering (Annealing): Heating the plated sheet above tin’s melting point creates a bright surface and a thin tin-iron alloy layer, improving corrosion resistance and solderability.

Passivation: Electrolytic treatment in 20–30 g/L sodium dichromate solution prevents yellowing or black spots.

Oiling: Thin DOS oil layer (2–4 mg/m²) protects the surface from scratches and oxidation during storage and processing.

| Process | Purpose |

|---|---|

| Pre-Treatment | Clean surface for plating |

| Electroplating | Deposit tin layer |

| Soft Soldering | Bright surface, corrosion resistance, better solderability |

| Passivation | Prevent discoloration and sulfur corrosion |

| Oiling | Lubrication and oxidation prevention |

Tinplate must meet GB/T 2520-2000 standards for cold-rolled tin-coated steel. Printing, also called “offset tinplate printing”, involves multiple stages:

Surface Preparation: Pre-baking at 200°C for 15 minutes removes excess oil to ensure proper ink adhesion.

Primer Coating: Ensures adhesion of colored inks and mechanical durability; commonly 14±2 g/m² white primer is used.

Color Printing: Multi-color printing requires accurate registration and cleaning of ink rollers to avoid color contamination.

Varnishing: Protective layer increases gloss, hardness, flexibility, and corrosion resistance.

Drying: Tunnel ovens with heating, constant temperature, and cooling zones, at 150–180°C for 10–15 minutes, ensure stable coatings without scratching or sticking.

| Printing Step | Key Requirements |

|---|---|

| Pre-Baking | 200°C, 15 min, remove excess oil |

| Primer Coating | Strong adhesion, 14±2 g/m² thickness |

| Color Printing | Accurate registration, ink roller cleaning |

| Varnishing | Gloss, flexibility, corrosion resistance |

| Drying | 150–180°C, 10–15 min, proper cooling |

Since tinplate edges are prone to rust, the industry typically bends and flattens edges or uses sealing adhesives to prevent corrosion. Standard tests include:

Crosshatch adhesion test

Alcohol rub test

Fumigation test

HB pencil hardness test

24-hour salt spray test

From a manufacturing standpoint, tinplate remains the material of choice for premium metal packaging due to its versatility, durability, and aesthetic appeal. While high initial investments in printing and prototyping may challenge small-scale producers, mass production allows brands to maintain quality consistency while controlling costs. Manufacturers are also increasingly adopting environmentally friendly tinplate coatings and passivation techniques, aligning with global sustainability goals. In the coming years, advancements in automated printing and surface treatments are expected to further enhance the efficiency and quality of tinplate production.