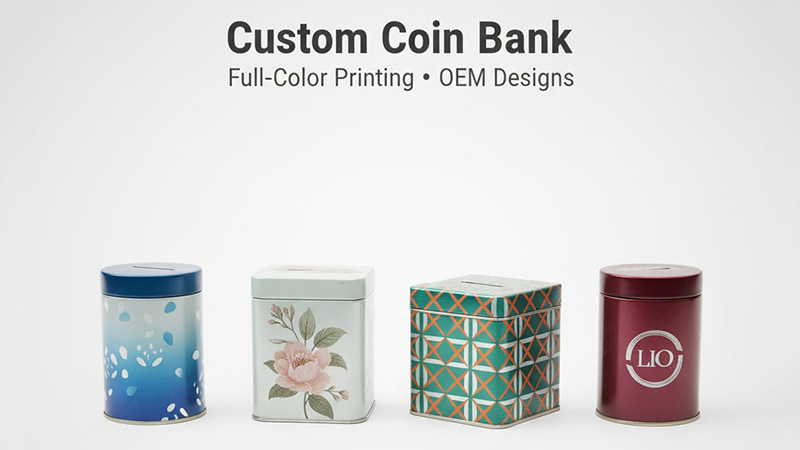

Metal coin banks may look like simple gift items, but for many brands, retailers, and promotional companies, they are reliable tools for marketing, children’s products, and seasonal campaigns. In recent years, B2B demand for metal coin banks has grown steadily. Buyers from gift companies, toy importers, supermarkets, and licensing brands continue choosing metal coin banks over plastic or ceramic options—mainly because of durability, branding flexibility, and cost-effective customization.

This guide explains what B2B purchasers usually consider when sourcing metal coin banks, what shapes and printing options are available, and how to evaluate manufacturer capability before placing an order.

When global buyers compare tin coin banks with plastic, the difference is not only about appearance. Tinplate brings several practical advantages that matter in B2B scenarios:

Metal coin banks made from tinplate resist pressure, scratches, and dents better than plastic. They don’t crack during transportation, and they can maintain shape even when stacked—important for bulk shipments and retail displays.

Brands using metal coin banks for promotions or children’s gift packs often want packaging that feels “special.” Tinplate has a naturally smooth, glossy surface that makes printed designs look more vivid. This helps buyers position products as mid-to-premium items without increasing cost significantly.

Tinplate is widely recyclable and accepted in most waste-sorting systems. For overseas buyers focusing on sustainability, metal coin banks allow them to meet environmental commitments without changing product functionality.

Plastic often limits color density or detail. Tinplate supports fine CMYK printing, Pantone colors, metallic effects, embossing, and matte/gloss finishes—ideal for branding, character licensing, and seasonal artwork.

B2B buyers usually look for metal tin money box that fit different campaigns, promotions, or retail themes. While manufacturers can create many custom shapes, a few practical tin coin bank formats remain the most efficient for large-volume production and consistent branding.

Many buyers ask for lock-and-key versions for:

Lock sets can be added to most standard shapes with minor tooling adjustments.

Printing quality is one of the first things buyers check during sampling. Understanding what is possible helps buyers judge manufacturers more accurately.

Suitable for cartoon artwork, promotional designs, and complex visuals.

Good for licensed brands that require accurate color matching.

Used when brand colors must be precise.

Highly recommended for corporate promotions.

Adds depth to logos, characters, or text.

Works well for premium product lines or collector editions.

Each creates a different visual effect.

Buyers often request matte finish for minimalist styles and glossy finish for children’s themes.

High-quality factories will apply protective varnish to reduce color fading or scratching during transport.

This is an important question to ask before confirming a supplier.

Many overseas buyers work with limited information. They must rely on product samples, factory catalogs, and communication with sales teams. Below are the main decision points:

Tinplate thickness influences durability and cost.

Common ranges: 0.21–0.30 mm.

Thicker material is better for large-size coin banks or lockable models.

Using existing molds can reduce costs significantly.

Custom molds require investment and lead time (often 25–35 days).

Buyers usually start with digital proofs, followed by a physical sample.

Stable color output is a key sign of manufacturer capability.

Standard coin banks often have MOQ of 3,000–5,000 pcs.

Custom shapes require higher quantities because of tooling costs.

To avoid scratches or deformation:

A good factory will provide detailed packaging photos.

Typical production timeline:

For children’s products, some markets require:

Asking this early helps avoid delays.

Overseas buyers often need a simple way to evaluate tin money box suppliers. Below is a practical, non-marketing checklist they can use:

More existing molds = more flexibility and faster sampling.

Factories with in-house printing have better color control and faster turnaround.

Good packaging standards reduce risk during long-distance shipping.

Tinplate grade, thickness, and coatings should be clearly listed.

A reliable factory can produce an accurate sample before mass production.

Clear replies about customization, artwork format, and lead time help reduce project risks.

This checklist allows buyers to compare manufacturers objectively and choose based on real needs—not just price.

Metal coin banks continue to serve as a practical product for gifting, retail, fundraising, children’s items, and seasonal promotions. Their durability, print quality, and environmental advantages make them a stable choice for buyers who want long-term value at a reasonable cost.

For B2B customers, the real decision comes down to:

This guide aims to help buyers make well-informed decisions and understand what to expect when sourcing metal coin banks from professional manufacturers.